The 2015 Bourbon Crusade: Jim Beam

Friday, April 10, 2015

Day 1 of the 2015 Bourbon Crusade officially began at 10AM at the Jim Beam American Stillhouse in Clermont, Kentucky. We woke early to ensure that we did not miss anything: today, we were kids on Christmas morning. I chose our home base based on its strategic location, and Clermont was thirty minutes away via I-265 and I-65. The Jim Beam American Stillhouse is less than two miles off of I-65 at mile marker 112. You are first greeted by the iconic white barn emblazoned with the red Jim Beam stamp and ribbon and sitting just off of Happy Hollow Road. We pulled up in front of the Jim Beam American Stillhouse just before 10AM. I exited the car and was hoping to catch that first whiff of the most intoxicating smell in the world—evaporating bourbon, grain (whole, ground and spent), wood and earth, a smell which I have yet to find in any of the dozens of candles each distillery labels as “Bourbon.” It was a chilly but clear and sunny morning, which meant that the smell was rising to the heavens and was not hanging like an invisible fog over the parking lot. Nevertheless, we moved towards the Jim Beam American Stillhouse standing in all its sparkly new construction faux antique glory, and, in fact, Mr. Jim Beam was there to greet us, waving his widebrim hat back in the direction of the front door beckoning our welcome.

We pulled up in front of the Jim Beam American Stillhouse just before 10AM. I exited the car and was hoping to catch that first whiff of the most intoxicating smell in the world—evaporating bourbon, grain (whole, ground and spent), wood and earth, a smell which I have yet to find in any of the dozens of candles each distillery labels as “Bourbon.” It was a chilly but clear and sunny morning, which meant that the smell was rising to the heavens and was not hanging like an invisible fog over the parking lot. Nevertheless, we moved towards the Jim Beam American Stillhouse standing in all its sparkly new construction faux antique glory, and, in fact, Mr. Jim Beam was there to greet us, waving his widebrim hat back in the direction of the front door beckoning our welcome. Inside stood most of the crusaders, already snapping pictures and taking notes. Just moments later, Craig Weiter, the Single Barrel Manager at the time and self-labeled luckiest employee at Jim Beam Brands, walked up and introduced himself to our group. We followed Craig back out the front door as tens of people were already showing up to shop, browse, and tour this piece of the Jim Beam operation, and we loaded into a red tour bus mocked up with aging barrels.

Inside stood most of the crusaders, already snapping pictures and taking notes. Just moments later, Craig Weiter, the Single Barrel Manager at the time and self-labeled luckiest employee at Jim Beam Brands, walked up and introduced himself to our group. We followed Craig back out the front door as tens of people were already showing up to shop, browse, and tour this piece of the Jim Beam operation, and we loaded into a red tour bus mocked up with aging barrels. Craig gave us the standard history lesson as we wound our way around the single barrel processing and bottling facility, the stillhouse, and up to Warehouse K where every person with the good fortune of participating in a Jim Beam single barrel program selection will pop the bung, pour, nose, sip and argue over about three different barrels of Jim Beam Brand bourbon.Today, we were selecting our own barrel of Knob Creek Single Barrel Reserve.As we circled the water reservoir and parked in front of Warehouse K, Craig said, “Gentlemen, today we are not going to taste a barrel younger than 10 years old.” A truthspeaker asked if Craig was able to meet our particular honey hole requests. “Yes, I pulled the barrels from [redacted] and [redacted], as you guys asked,” said Craig. I couldn’t wait.

Craig gave us the standard history lesson as we wound our way around the single barrel processing and bottling facility, the stillhouse, and up to Warehouse K where every person with the good fortune of participating in a Jim Beam single barrel program selection will pop the bung, pour, nose, sip and argue over about three different barrels of Jim Beam Brand bourbon.Today, we were selecting our own barrel of Knob Creek Single Barrel Reserve.As we circled the water reservoir and parked in front of Warehouse K, Craig said, “Gentlemen, today we are not going to taste a barrel younger than 10 years old.” A truthspeaker asked if Craig was able to meet our particular honey hole requests. “Yes, I pulled the barrels from [redacted] and [redacted], as you guys asked,” said Craig. I couldn’t wait. Warehouse K is a seven-story metal-sided rickhouse that sits partially up a hill with relatively total exposure to the elements. You enter Warehouse K through a patio that also serves as a loading dock. We walked in and—BAM!—there was the most intoxicating smell in the world. And cold! It was probably in the mid to high-50s in the sun, but the bottom floor of Warehouse K was no warmer than the mid-40s at 10:15AM. The windows were open to allow the airflow that you always hear about on bourbon tours, and the breeze was just as cold as the bourbon-soaked air inside. To your left upon entering is a long line of tasting tables—bars about elbow high with three Knob Creek glasses (red, green and blue) and a pitcher of water for each person on the tasting.

Warehouse K is a seven-story metal-sided rickhouse that sits partially up a hill with relatively total exposure to the elements. You enter Warehouse K through a patio that also serves as a loading dock. We walked in and—BAM!—there was the most intoxicating smell in the world. And cold! It was probably in the mid to high-50s in the sun, but the bottom floor of Warehouse K was no warmer than the mid-40s at 10:15AM. The windows were open to allow the airflow that you always hear about on bourbon tours, and the breeze was just as cold as the bourbon-soaked air inside. To your left upon entering is a long line of tasting tables—bars about elbow high with three Knob Creek glasses (red, green and blue) and a pitcher of water for each person on the tasting. To your right are your potential barrels nesting on the floor next to rick tiers filled with thousands of 53 gallon barrels.

To your right are your potential barrels nesting on the floor next to rick tiers filled with thousands of 53 gallon barrels. Everywhere the evaporating bourbon and old wood musk clogs the air. Once we were all in and stationed, Craig asked if we wanted to know the ages of our barrels. The answer was “No.” The age was stamped on the barrel for all to see if you knew how to read the code but we did not want to let age bias our picks.Craig demonstrated how to open the barrel, which requires a wooden mallet that you hit either side of the bung with until it pops out. There are easier methods, such as a bung reamer or, as we saw at Willett later, a standard Craftsman drill right to the barrel cap. I opened the second barrel, and once all three were open, we lined up like schoolchildren and made our way single-file to Craig and the thief to get a taste of Knob Creek, first red, then green, then blue. Our barrels, we later found out, spanned a 126 to 137 proof range.

Everywhere the evaporating bourbon and old wood musk clogs the air. Once we were all in and stationed, Craig asked if we wanted to know the ages of our barrels. The answer was “No.” The age was stamped on the barrel for all to see if you knew how to read the code but we did not want to let age bias our picks.Craig demonstrated how to open the barrel, which requires a wooden mallet that you hit either side of the bung with until it pops out. There are easier methods, such as a bung reamer or, as we saw at Willett later, a standard Craftsman drill right to the barrel cap. I opened the second barrel, and once all three were open, we lined up like schoolchildren and made our way single-file to Craig and the thief to get a taste of Knob Creek, first red, then green, then blue. Our barrels, we later found out, spanned a 126 to 137 proof range. We decided the easiest way to pick between three barrels would be to kick out the least liked barrel in round 1. After the tally was complete, about 80% of our group liked the red barrel the least. Then, it was green versus blue. In the end, blue was the runaway favorite. Runaway. In fairness, I picked green, then blue, then red; but, I was only one of two that did not pick blue.I was running high after the pick, and I thought our time at Jim Beam was coming to a close. We had a tour at Independent Stave penciled for 1PM. We watched Craig roll the barrel onto a truck bed to be sent to bottling and piled back on the red tour bus to the single barrel processing and bottling facility. The bus stopped outside the microdistillery, and Craig began to give us a tour of the distillery. I took a look at my watch and realized that we were going to miss Independent Stave. I apologize to Independent Stave that we had to cancel, but there will be other crusades.

We decided the easiest way to pick between three barrels would be to kick out the least liked barrel in round 1. After the tally was complete, about 80% of our group liked the red barrel the least. Then, it was green versus blue. In the end, blue was the runaway favorite. Runaway. In fairness, I picked green, then blue, then red; but, I was only one of two that did not pick blue.I was running high after the pick, and I thought our time at Jim Beam was coming to a close. We had a tour at Independent Stave penciled for 1PM. We watched Craig roll the barrel onto a truck bed to be sent to bottling and piled back on the red tour bus to the single barrel processing and bottling facility. The bus stopped outside the microdistillery, and Craig began to give us a tour of the distillery. I took a look at my watch and realized that we were going to miss Independent Stave. I apologize to Independent Stave that we had to cancel, but there will be other crusades. The tour began at the grain mill and microdistillery building. You enter into a dark room with a metal grate over one end of the room; the grate covers a water source that gives off a mildew smell. As you exit the dark room, you enter the microdistillery which contains a grain exhibit with a small grain cooker, which was cooking as we were walking through. At the top of some stairs in the microdistillery sat a few fermenters.

The tour began at the grain mill and microdistillery building. You enter into a dark room with a metal grate over one end of the room; the grate covers a water source that gives off a mildew smell. As you exit the dark room, you enter the microdistillery which contains a grain exhibit with a small grain cooker, which was cooking as we were walking through. At the top of some stairs in the microdistillery sat a few fermenters. Ever since my first bourbon tour (Hard Hat Tour at Buffalo Trace), I have been in awe of fermenters. It is in the fermenters where the yeast works to convert sugars to alcohol to form distiller’s beer, which means it is in the fermenters where the magnificent K yeast at Four Roses sets in motion the alcohol production for some of the very best bourbon in the industry. After leaving the microdistillery, we headed to the big stillhouse with its larger fermenters and a seventy-plus foot column still churning and smoking behind a separate glass front. Two workers sat opposite the stillroom in command control working the computers in the stillhouse, and they came out to pull some high wine off of the still for us to taste. We were told that the high wine was Old Grand Dad. The Old Grand Dad white dog was intensely strong and flavorful, with a punch on the fumes that could singe nose hair, but a creaminess that we decided was melted orangesicle.

Ever since my first bourbon tour (Hard Hat Tour at Buffalo Trace), I have been in awe of fermenters. It is in the fermenters where the yeast works to convert sugars to alcohol to form distiller’s beer, which means it is in the fermenters where the magnificent K yeast at Four Roses sets in motion the alcohol production for some of the very best bourbon in the industry. After leaving the microdistillery, we headed to the big stillhouse with its larger fermenters and a seventy-plus foot column still churning and smoking behind a separate glass front. Two workers sat opposite the stillroom in command control working the computers in the stillhouse, and they came out to pull some high wine off of the still for us to taste. We were told that the high wine was Old Grand Dad. The Old Grand Dad white dog was intensely strong and flavorful, with a punch on the fumes that could singe nose hair, but a creaminess that we decided was melted orangesicle. Fantastic white dog. I had two samples. From there, we walked back towards the single barrel processing and bottling facility to watch our barrel show up from the truck.The bottling facility has a loading dock to the side; up pulled the truck with our barrel, and it was off-loaded onto a platform above a metal bed covered in bourbon-soaked charcoal. A hole sat in the center of the metal bed, which fed a pipe that ran into a large 53-gallon graduated cylinder that hung on the wall next a large sign that read “Knob Creek.” My dad did the honors of using the bung reamer to drill out the bung and start emptying the barrel into the metal bed. As the bourbon flowed out, Craig snagged a glass straight from the barrel for one more pass around with the group.

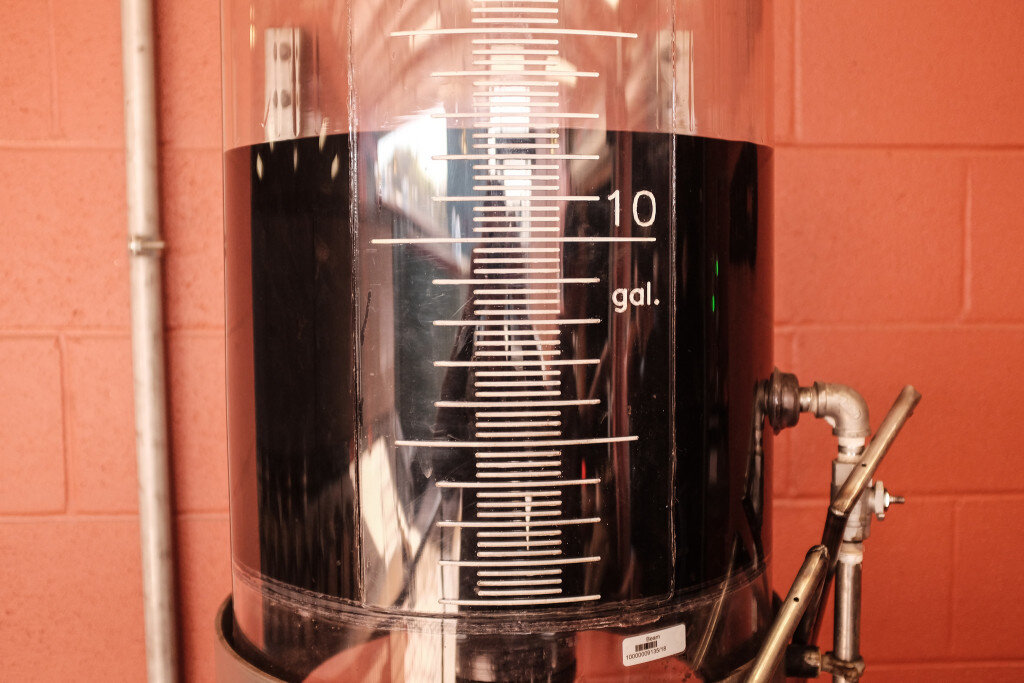

Fantastic white dog. I had two samples. From there, we walked back towards the single barrel processing and bottling facility to watch our barrel show up from the truck.The bottling facility has a loading dock to the side; up pulled the truck with our barrel, and it was off-loaded onto a platform above a metal bed covered in bourbon-soaked charcoal. A hole sat in the center of the metal bed, which fed a pipe that ran into a large 53-gallon graduated cylinder that hung on the wall next a large sign that read “Knob Creek.” My dad did the honors of using the bung reamer to drill out the bung and start emptying the barrel into the metal bed. As the bourbon flowed out, Craig snagged a glass straight from the barrel for one more pass around with the group.

Craig pointed to the graduated cylinder and remarked that, from his time as the Single Barrel Manager, the standard private selection of Knob Creek Single Barrel produced between 30 and 35 gallons straight from the barrel. We started taking guesses. I was on the low end at 28 gallons. I heard as high as 38 gallons. We watched as the cylinder gurgled upwards with cold press coffee colored bourbon only for the gurgling to trickle to a stop at 17.5 gallons. Just 17.5 gallons!

Craig pointed to the graduated cylinder and remarked that, from his time as the Single Barrel Manager, the standard private selection of Knob Creek Single Barrel produced between 30 and 35 gallons straight from the barrel. We started taking guesses. I was on the low end at 28 gallons. I heard as high as 38 gallons. We watched as the cylinder gurgled upwards with cold press coffee colored bourbon only for the gurgling to trickle to a stop at 17.5 gallons. Just 17.5 gallons! I note again that this was the youngest barrel we tasted at just 10 years and 1 month. Just 17.5 gallons! Nobody, not even Craig, saw this coming. Craig had to settle down the chirping and Ric Flair wooing in our group to tell us that we still had to bottle our pick, but that we had to eat lunch while they did the evil task of filtering and proofing down our barrel. So, of course, we started taking guesses on how much was needed to proof down our barrel from ??? proof to 120 proof. At just 17.5 gallons, with guesses of 2-3 gallons of water, we started counting sheep in our head, with the sheep being the number of bottles we were actually going to get out of this barrel.When we arrived back at the American Stillhouse, Craig said that lunch was on Jim Beam, so we headed down to Fred’s Smokehouse conveniently located on site for some BBQ, and, after about a dozen pulled pork sandwiches and Ale 8-ones later, Craig whisked us back down to the bottling facility to bottle our product.

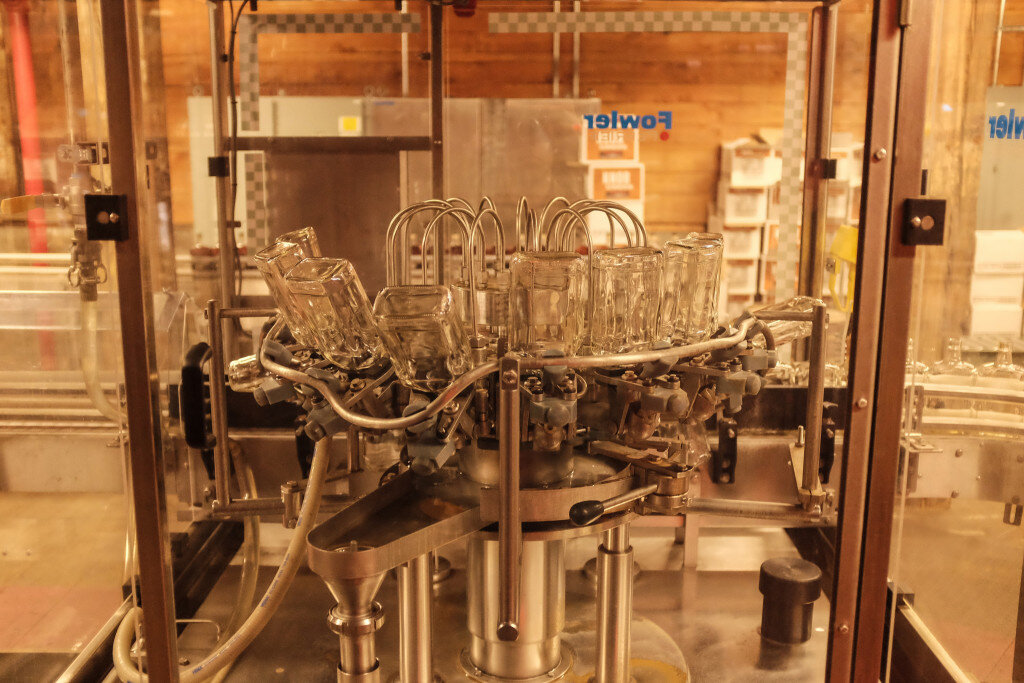

I note again that this was the youngest barrel we tasted at just 10 years and 1 month. Just 17.5 gallons! Nobody, not even Craig, saw this coming. Craig had to settle down the chirping and Ric Flair wooing in our group to tell us that we still had to bottle our pick, but that we had to eat lunch while they did the evil task of filtering and proofing down our barrel. So, of course, we started taking guesses on how much was needed to proof down our barrel from ??? proof to 120 proof. At just 17.5 gallons, with guesses of 2-3 gallons of water, we started counting sheep in our head, with the sheep being the number of bottles we were actually going to get out of this barrel.When we arrived back at the American Stillhouse, Craig said that lunch was on Jim Beam, so we headed down to Fred’s Smokehouse conveniently located on site for some BBQ, and, after about a dozen pulled pork sandwiches and Ale 8-ones later, Craig whisked us back down to the bottling facility to bottle our product.  The Knob Creek Single Barrel bottling line is a great setup needing no more than three men for the union job. We watched as they unpacked our empty glass bottles onto the line, and the first stop for the bottles is the washing station. The washing station flips the bottles upside down and blasts bourbon into the glass to wash them of dust, cardboard and shards.

The Knob Creek Single Barrel bottling line is a great setup needing no more than three men for the union job. We watched as they unpacked our empty glass bottles onto the line, and the first stop for the bottles is the washing station. The washing station flips the bottles upside down and blasts bourbon into the glass to wash them of dust, cardboard and shards. Why bourbon and not water? Jim Beam Brands does not want to water down or alter the flavor of your single barrel bourbon. There was a one-bottle station to add to the customer experience, and we each got to wash our own bottle and place it back into the line as it made its way to be filled. When we went to the second level above the bottling line to see our proofed down barrel being loaded into the bottling pipe, we found out that it took just over 2 gallons of water to get us to about 120.2 proof.For those keeping score at home, our barrel produced just under 20 gallons of bourbon out of a 53 gallon barrel after 10 years and 1 month in [redacted] position on [redacted] floor of Warehouse K. We jaunted back down to the first floor to watch the juice hit the empty bottles and get the new labels.

Why bourbon and not water? Jim Beam Brands does not want to water down or alter the flavor of your single barrel bourbon. There was a one-bottle station to add to the customer experience, and we each got to wash our own bottle and place it back into the line as it made its way to be filled. When we went to the second level above the bottling line to see our proofed down barrel being loaded into the bottling pipe, we found out that it took just over 2 gallons of water to get us to about 120.2 proof.For those keeping score at home, our barrel produced just under 20 gallons of bourbon out of a 53 gallon barrel after 10 years and 1 month in [redacted] position on [redacted] floor of Warehouse K. We jaunted back down to the first floor to watch the juice hit the empty bottles and get the new labels. The next stop on the line was the private label station. I took our barrel plaque and placed it on the door and the group began placing the plaques on each of our bottles. If you are lucky enough to grab a bottle, you may notice an upside down or crooked plaque: consider those bottles special. After labeling came waxing, which was done by a union worker who let my wife place a thumbprint in the cap of one of our bottles—you will not be seeing this bottle anywhere in the wild. When all was said and done we got a whopping 93.5 bottles. I am certain that less than a third of these hit the shelves.Tasting notes? Black cherry cordial bomb.

The next stop on the line was the private label station. I took our barrel plaque and placed it on the door and the group began placing the plaques on each of our bottles. If you are lucky enough to grab a bottle, you may notice an upside down or crooked plaque: consider those bottles special. After labeling came waxing, which was done by a union worker who let my wife place a thumbprint in the cap of one of our bottles—you will not be seeing this bottle anywhere in the wild. When all was said and done we got a whopping 93.5 bottles. I am certain that less than a third of these hit the shelves.Tasting notes? Black cherry cordial bomb. In sum the whole of our Jim Beam American Stillhouse experience took four hours, and we were bumping against a timing issue with our trip to Maker’s Mark. We already had to cancel Independent Stave, and we could not miss Maker’s Mark, especially after hearing a summary of what the tour would entail. The plan leaving Jim Beam was to make a quick stop at Willett to let group members have access to an extra day’s allotment of Willett Family Estate or for those that couldn’t make Monday to have a chance to buy Willett Family Estate. Fortunately, Willett is in the general direction of Maker’s Mark so we left Jim Beam and hit the Kentucky back roads to Bardstown.

In sum the whole of our Jim Beam American Stillhouse experience took four hours, and we were bumping against a timing issue with our trip to Maker’s Mark. We already had to cancel Independent Stave, and we could not miss Maker’s Mark, especially after hearing a summary of what the tour would entail. The plan leaving Jim Beam was to make a quick stop at Willett to let group members have access to an extra day’s allotment of Willett Family Estate or for those that couldn’t make Monday to have a chance to buy Willett Family Estate. Fortunately, Willett is in the general direction of Maker’s Mark so we left Jim Beam and hit the Kentucky back roads to Bardstown.